Transfer Press Solutions

In destacker projects the positions and movement axis of destacker loading carts and cartesian robot structure being specially designed according to working speed of transfer press and blank dimensions. According to this destacker loading carts can be moveable side by side and front or back. In addtion, destacker loading carts can be placed at right and left, only right or only left and also behind the conveyor. Our destacker systems can work %100 compatible with every brand of transfer press. This allows working ability with different type of lines as press to press transfer, inside press transfer and tandem press lines.

Press Transfer Systems can be presented as a solution for all kind of transfer presses depending on different type of speed expectations.

Additionally, Press Transfer Robots can provide flexible and efficent solutions for press to press transfer operations.

Destacker System General Specifications

- - Working Speed up to 30spm

- - Magnetic and Non-Magnetic Material Working Ability

- - Automatic Station Change

- - Loading Station positions as paralel or transverse direction to flow direction

- - Easy and fast vacuum set change with Quick Change cartesian unit - Double sheet control on each unit for both magnetic and non-magnetic materials

Destacker Loading Station

Time loss during material load can be prevented by double loading station and automatic station change. With the servo motorized lifting unit completely placed inside the loading station there’s no need for foundation for lifting system.

Destacker Rotating Unit

It’s possible to use different sizes of sheet from the coil at same width with the servo driven rotating unit, which can be applied on destacker cartesian unit or separately. The variety of stock coils decreases and usability of a single width coil in different operation increases. This provides advantages about stock space, supply costs and production flexibility.

Shuttle

- - Adjustable structure for different kind of parts references

- - Up to 20 spm maximum working speed with dynamic and strong structure

- - Fixed movement axis or telescopic movement ability

PRESS TRANSFER SYSTEMS

Press transfer systems designed for working between press columns or at front and back side of press regarding the structure of press which transfer operation will be made. This allows the system to work compatible with every type and brand of hydraulic transfer presses, eccentric transfer presses and servo transfer presses.

Additionally complete line can be configurated with press feeding system and destacker separately or both together to work before the transfer system. Various solutions can be offered for parts carriage between presses with Press Transfer Robots for press to press transfer operations.

Press Transfer Systems General Specifications

- -Working Speed up to 30spm

- -3 Programmable Axis

- -Transfer Bar Dimensions Which Specified According to Transfer Press Bolster Dimensions

- -Automatic Bar Change

- -Automatic Air and Electric Connections

- -Rack and Pinion Driven Axes

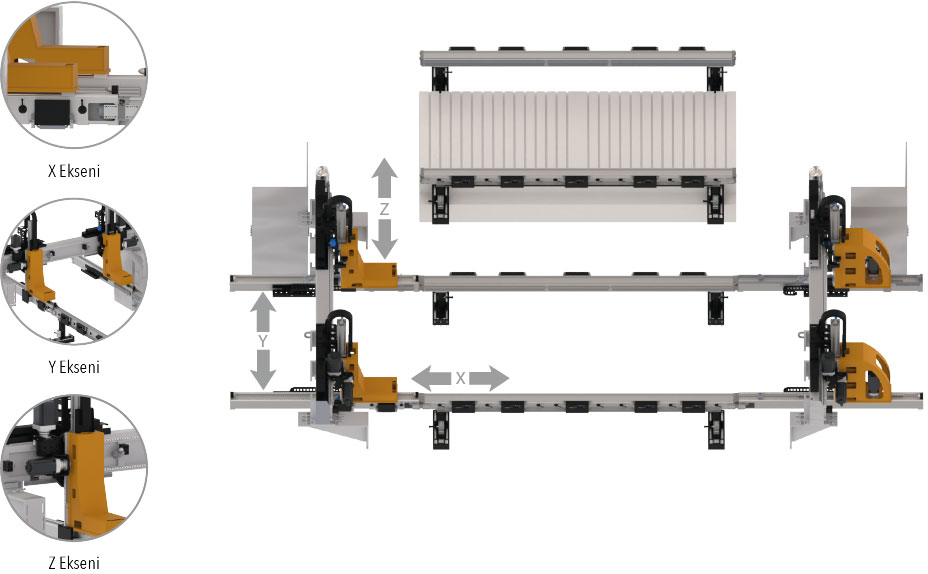

Transfer Axis Movements

- -X Axis

- X axis maximum movement distance up to 1800mm

- - Y Axis

- Y axis movement being defined depending on transfer press upright dimensions

- - Z Axis

- Z axis maximum movement distance up to 350mm

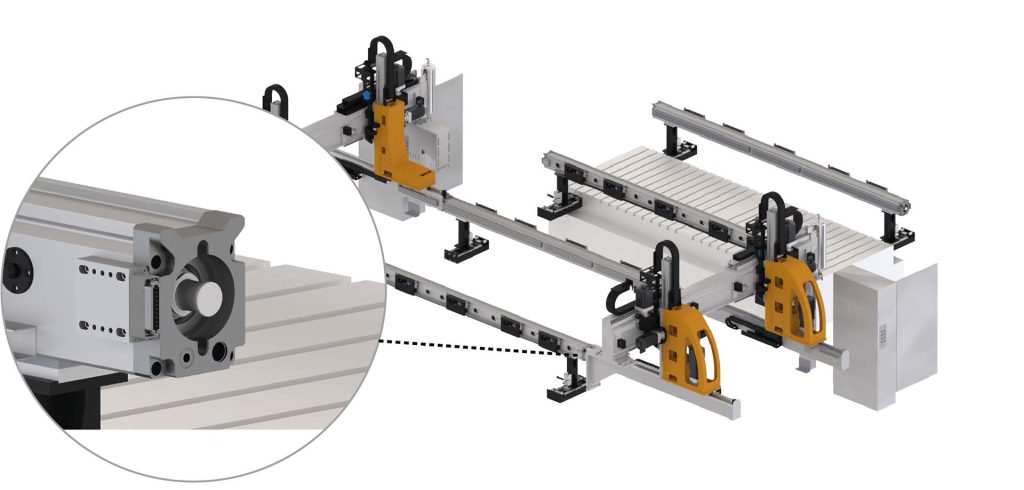

Transfer Bars Locking System

Transfer bars can be picked and droped automatically. This application can be done with pneumatic driven automatic locking system. During this operations also the air and electric connections being made automatically. With case-hardening steel guide structure all the operations being made as centered without any damage on the locking system. Additionally bars are not released with specially designed locking structure even at air cut.

Dynamic Torque Control

With Dynamic Torque Control, transfer system stops instantaneously when defined limit torque value reached. This allows preventing occupational accidents and damages.

PRESS TRANSFER ROBOTS

Press Transfer Robots are system designed for press to press transfer operations. Transfer type between presses could change depending on press type, structure of tools and process. According to these variables one of T Robot, Monobar Robot, V Robot and Bar Feeder options can be selected.

3 axis Press Transfer Systems can be prefered for transfer press solutions.

T Robot

- -2 axis, strong and dynamic structure

- - 5500mm axis range at high speed

- - 4200ms cycle time

Monobar Robot

- - Drive group design with low space requirement

- -5500mm axis range at high speed

- -4200ms cycle time

V Robot

- -Movement ability up to 4 axis

- - Easy panel control and robot programming

- - Body rotation with low backlash gearbox