Universal Lathe

Universal Lathe

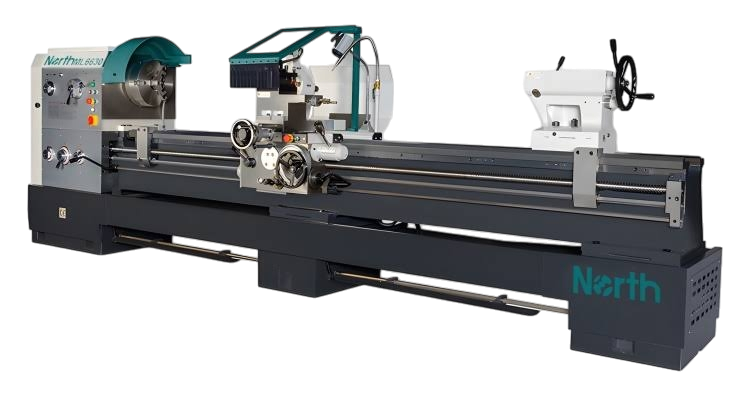

A machine that is widely used in the machinery and metal sector, performs chip removal with cutting tools that move linearly on metal and artificial materials rotating around its own axis, and does not have a numerical control system is called a universal lathe. There are many options in the universal lathe category depending on the features of the machine. In addition, one of the important features that diversify the machines is the countries that make the production. The choice of lathe is determined according to the features of the part that the machine will process. The length and diameter of the part come to the forefront among these features. Therefore, when making a choice, the most important point is to purchase a machine suitable for the part to be processed. The majority of lathes on the market are imported products. Lathes with standard features are usually found in the stocks of companies. However, lathes with some optional features or large sizes are usually not kept in stock and are produced on order. Therefore, the supply of the ordered lathe takes a certain amount of time.

These machines, which are frequently used in the metal sector, are quite practical products. There are many models of lathes. These are;

Universal lathe

Table lathe

Watchmaker's lathe

Electronic controlled lathe

Hydraulic controlled lathe

Universal lathes are divided into many categories within themselves. Tos lathe is one of them. Two brands stand out in the Tos lathe category. One of these is the Slovak Tos Lathe, known as Trens brand Slovakian origin lathes. Although the SN50C model is generally preferred, SN71C models are also popular for larger workpieces. In the universal lathe category, the Iranian origin MST Tabriz brand Iran Tos Lathes are among the preferred universal lathes in the sector as a competitor to the Trens brand Tos lathes. The most preferred model among the MST Tabriz Iran Tos Lathes is the TN50BR model. MST Tabriz brand Tos lathes are more affordable than Slovakian origin Trens lathes. They are designed for part and mass production. They are also widely used in maintenance and repair work. They are sensitive and very reliable machines.

These machines, which have been used in production for many years, have always maintained their place among the basic building blocks of production. They work for a long time thanks to their easy maintenance. They are highly preferred by users due to their low operating cost. They have ground and hardened gears. They are preferred by companies due to the work they do. Having a low cost is an important detail in the machinery sector. Since the parts purchased are of foreign origin, their prices vary, and these rates can be high or low depending on foreign exchange movements. However, since each product is different, it is possible to find lower-cost products.

There is a section between lathes and milling machines. They both perform drilling and chip removal. However, while the part to be processed in a lathe rotates, the cutters of the machine are more fixed. In milling, the part to be processed is fixed, but the cutters of the machine move on the parts.